Painting line with Giardina GS 20 robot (installation, commissioning and training included in the price. Transport paid separately)equipped with:

1. LOADING -Antistatic PVC conveyor belt with solvent resistant coating Adjustable feed speed controlled by an inverter Total dimensions: mm. length 3,000 x 1,700 x 900 h.

• Brush machine – a cleaner with rotating blowing nozzles with deionizing strip • Electronic reading of the arrangement of fed elements on the loading belt

2. PAINTING – Robot in the painting booth

• Enclosing the booth to create a protected room in which the coating and drying operation can be carried out under the most appropriate environmental conditions

• Conveyor belt inside the spray area Transport system inside the spray booth consisting of a perforated PVC tape that supports disposable paper or thin-film tape (1700 mm wide). The system is complete with winding and unwinding units, film tensioning device using a fractionated motor. The vacuum system guarantees a perfect connection between PVC and paper tapes.

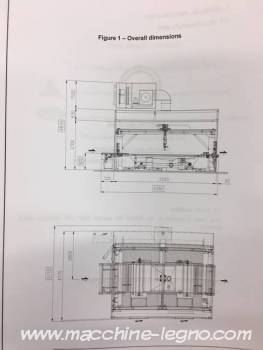

• CNC spraying robot with 5 axes mod. Gardina GS 20 Supports two guns - Two paint circuits CNC 5 axis robot movement as follows: Feed speed (B axes) - adjustable from 5 to 15 m/min using an inverter Longitudinal travel (X axis): 4,500 mm. - Movement on sliding guides made of cement, steel and ball carriages - CNC controlled. Max. Speed of reciprocating movement: 110 m/min. Transverse course (Y axis): 2,200 mm. - Movement on sliding guides made of cemented steel and ball guides - CNC controlled Max. Reciprocating speed: 110 m/min Rotation (A axis): directly on the arm using a toothed belt (timing) gear - CNC controlled Head tilt (W axis): from 0 to 180 degrees using a pneumatic system Electronic control system, using an NC control unit, controlling the spray guns and the sequence of movement of the painting head. It is connected to a PC using Windows XP software. The NC unit is able to control linear interpolation as well as circular interpolation. Reading strip at the machine inlet with 132 photocells Switchgear protection level: IP 55 - Motors and lighting installation in the shower area are explosion-proof, other motors outside have IP 55 protection. Manufactured in accordance with CE standards Required thermal efficiency: Kcal/h 80,000 Installed power: KW. 25 Approximate compressed air consumption for guns and pumps (this value may vary depending on the number of guns and pumps): lt/min 2,000 Volume of air removed from the room: m3/h 16,000

3. UNLOADING Roller conveyor

- Poland

- uzate