DIPPING TANKS FOR WOOD IMPREGNATION - “DT” MODEL

In this type of plant, wood impregnation is achieved by immersion of semifinished product

into a heavy duty tank filled with the preservative solution.

Wooden products are placed on a fork and locked with an anti-floating device. The fork

(moved with a control push-button with cable) moves vertically down into the tank.

This type of machine is used for the treatment of wood in risk class II (according to the UNI EN 335-1 - Table A), ie, the wood treated with these plants is protected by casual contact humidity

Technical details:

» Tank made in heavy duty carbon steel sheet, with reinforcements for containment of

preservative solution.

» Load fork for semifinished wood products, moved by a hydraulic cylinder.

» Pusher moved my a hydraulic cylinder, with anti-floating function for wooden products.

» Hydraulic power unit, provided with an electrical sensor for oil level.

» Manual lever valve, placed on the bottom of the tank for solution discharge.

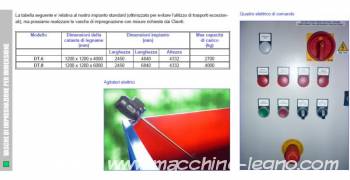

» Electrical mixers (n°2) for preservative solution mix.

» Electrical panel for control.

» Control push-button with cable (L=10 m) for fork control at distance.

» Vertical motion mechanism designed for the highest reliability.

» Steel surface protection:

» Internal surfaces for tank and fork painted with bicomponent epoxy coating.

» External surface of tank painted with epxy primer and finishing synthetic paint.

» Options: automation of immersion with dipping time settable with a timer.

Our products are manufactured in compliance with the european laws that define the EU’s health,

safety and environmental protection requirements.

- Italy

- New