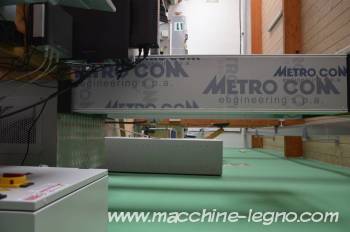

Electromechanical machine for tensile and universal tests - tests on wood, steel and composite materials.

Frame structure 10400020. Acquisition and control system 96000000

Technical features.

Nominal load 200 kN; max distance between tooth grafts: 920 mm .; distance min. between tooth grafts: contact; Test speed 0.1-250 mm / min .; distance between the uprights: 500 mm; Accuracy class UNI EN ISO 7500/1. Equipped with: compensated resistive load transducer; high resolution type transducer displacement transducer. Frame made up of ball screws, with preloaded nuts for play recovery; tempered and ground columns; two fixed and one movable crosspieces.

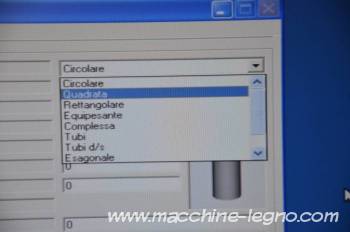

Self-tightening clamps complete with wedges for round tubes with a diameter of 8-18 mm. and flat 0-14 mm .; max width 50 mm. Set of jaws for: 6-20mm flat test tubes; round test tubes with a diameter of 3-8 mm; round test tubes diameter 18-26 mm. N. 2 displacement transducers with max. 100 mm. equipped with lower support bracket, upper eye attachment to facilitate fixing to the specimens.

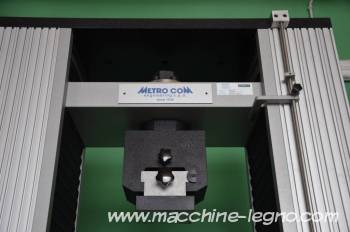

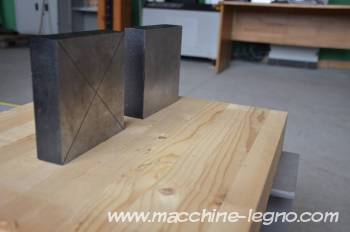

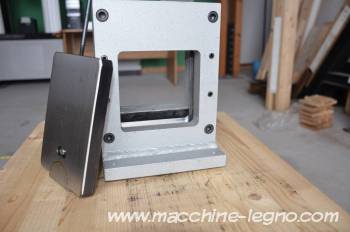

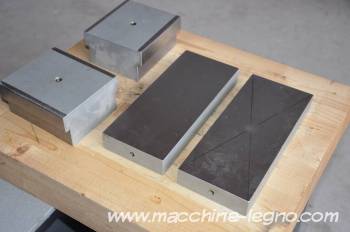

Element for application to the lower tooth coupling of the equipment; equipment for compression tests on wood consisting of: upper articulated compressor plate with dimensions of 147x147 mm. and rigid lower compressor plate with dimensions of 147x147 mm; compression test equipment consisting of: lower and upper compression plates of rigid type with dimensions of 147x147 mm. Bending test rig on wood for max. 30kN. Equipment for shear tests on wood, according to EN14080 (ex EN392) consisting of an upper thrust element with joint and lower support for the specimen with a height of 60 mm.

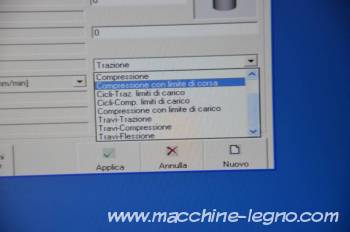

The 96000000 acquisition and control system consists of an external interface for conditioning the signals coming from the transducers mounted on the testing machine; high sampling rate and resolution signal acquisition and synchronization card; software dedicated to the visualization, printing and archiving of data and results, operating in a Windows environment. The basic software includes the: procedure for carrying out tensile tests without strain gauges with load / stroke graph; procedure for carrying out compression / bending tests without strain gauge with load / stroke graph of the mobile clamp; procedure for carrying out tensile tests with load / strain gauge and load / stroke graph of the mobile clamp; configuration procedure of the parameters of the displacement load of the proportionality Fp and of the load at the limit of total elongation Ft.

Procedure for calculating Agt according to the following methods: manual method, established by the reference standard (does not imply the use of the strain gauge); method with composition of the data of the load / stroke and load / deformation curves (implies the use of strain gauge); rigorous method, based on load / strain curve data (implies use of strain gauges).

All parameters can be defined even after the test has been performed; the software will automatically proceed with the reprocessing of the data and the recalculation of the relative quantities detected. Procedure for entering the technical data relating to the test (section, speed, distance between the terminals) also supported by images. Procedure for archiving test data and loading procedure for data already stored in formats readable by the most popular Office Automation programs. Procedure for choosing the numeric format for data display. Procedure for choosing the unit of measurement of the test quantities: N, kN and lb. Procedure for storing the "modalities" of the tests carried out in order to generate "test procedures". Procedure for changing (even after testing) the data units of measurement. Test execution procedure with real-time display of load, stroke and deformation values. Autoscale function for automatic and sequential tracing of diagrams with ratios: on the axis of loads 1/1 - 1/2 - 1/5 - 1/10 with respect to the rated load of the machine; on the axis relating to the travel of the mobile clamp / crossbar with ratios 1/1 - 2/1 - 5/1 - 10/1 with respect to the reference travel; on the axis relating to the deformation expressed by the strain gauge in the 1/1 - 2/1 ratio with the nominal strain of the strain gauge. Possibility of carrying out self-calibration to purge the test of the impact of the equipment. Procedure for customizing certificates by choosing (even after testing) the quantities and related geometric constructions. Procedure for customizing the entries and endorsements on the certificates; procedure to explain the geometric constructions used by the software to identify significant loads. Analysis of the graphs relating to the tests performed by point / point scrolling with the possibility of highlighting the coordinates of the points selected by the operator. Customization of printouts by choosing fonts, colors and formatting (logo, dimensions, etc.). Possibility of inserting the logo in bmp format. Printing of the "customized" test certificate by previewing to verify the output; you can save the certificate in HTML format for possible publication on the internet or intranet. Setting the range of limit values relating to elastic modulus, maximum load, elongation. Procedure for reading and checking the calibration values. The software allows to acquire: Fm (max load); A% (elongation according to various types); E (modulus of elasticity); 2 values of Fp (conventional yield) of your choice; Ft% (load of deviation from proportionality); Fu (last load); Z (pinching); Feh and Fel with relative unit loads

The software also included the following options: traction tests with load / stroke limits; compression tests with load / stroke limits; data saving on Excel; Simulation; second language (English); elongation correlation; automatic repositioning at the end of the test; panel used to display instantaneous speed or load gradient values; software for superimposing up to 8 test charts; low frequency cycles without stroke limits and tests with load limits (traction and compression). Summary program; statistical processing program.

PC with monitor included. CE Certification / ACCREDIA Certification / Use and maintenance manuals.

- Italy

- Second hand