TECHNICAL FEATURES MODEL

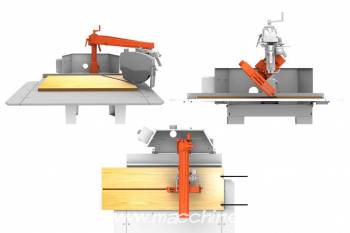

Radial-arm saw for straight (90°) cross cutting, ripping and bevel cutting at 45° left and right. The movement of the cutting unit along the arm, on guides and ball bearings, is manual, aided by a return spring, so is the blade tilting with mechanical locking system at 45° left. The pillar group is made of cast-iron and fixed on a solid frame and legs made of steel. Working bench in MDF. Manufactured according to EC standards.

Max. cutting height 125 mm

Max. cutting width 705 x 20 h mm

Min. cutting width 610 x 125 h mm

Max. length of workpiece: unlimited

Max. cutting width for ripping 1030 mm

Cutting height at 45 °0 - 80 mm

Min. and Max. cutting width at 45° (right) 430 - 500 mm

Min. and Max. cutting width at 45° (left) 240 - 310 mm

Height of blade from working bench 0 - 45 mm

Blade diameter 400 mm

Blade bore diameter 30 mm

MotorHP / KW 4/3 RPM 2800

Overall dimensions of full-assembled machine and net weight1690 x 1560 x h 1580 mm / 225 Kg

STANDARD EQUIPMENT

Automatic return-spring

Self-braking motor

Electrical system equipped with motor-overload protection and emergency button

Sound-insulated blade guard made of steel

Push-sticks for ripping

Well-dimensioned rear hood, ready to be connected to a dust collector

MDF working bench

Lockable switch

Package: recyclable cardboard box

Blade not included

For straight (90°) and miter (45° left) cross cutting, ripping and bevel cutting at 45° left and right, of wooden-based panels and solid wood boards up to 3mt. For furniture manufacturing and joinery.

- Small footprint: well suited to small workshops

- Easy to use

- Versatile

- Useful complement to panel saws

More than 30.000 machines manufactured, over fifty years' experience. 100% made-in-Italy machines abiding by the highest quality standards as a result of the "Lean" manufacturing process, also known as "Toyota System".

- Italy

- New