TECHNICAL FEATURES MODEL

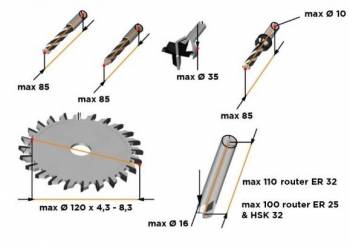

Easy programmable through-feed boring machines with easy-to-use, intuitive software, 3 controlled axis X,Y,Z, also performing grooving, and very basic milling operations (optional), working from underneath

Panel handling with pneumatic clamp and automatic lubrication of the axes

Machine manufactured according to EC standards

STANDARD EQUIPMENT

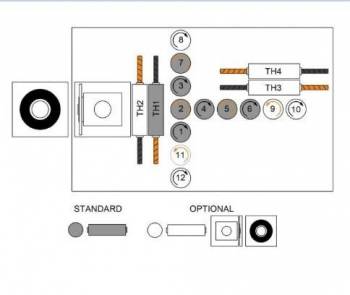

HEAD UNIT

Independent spindles

N.7 vertical spindles

N.1 double horizontal-spindle (TH1) for back and forth drilling

High-precision manual side aligner, sliding on ball bearings

Panel-edge detection with laser sensor for perfect panel joints

Teleservice software

Powerful dust-collection system and automatic blowers for effective cleaning of the boring head unit

Well-dimensioned working tables with rollers

Automatic lubrication of the axes-unique in its category!

Working in a cycle or back to the operator

Package: on a wooden pallet

HARDWARE & SOFTWARE

- OSAI OPEN LIGHT CNC System for job programming and remote connection

- PEGASUS PANEL – LIGHT VERSION Design software

- Industrial PC ,Win10 IoTE 64bit LTSC SSD128GB_MSATA/0C, 128GB PROGRAM MEMORY on mSATA SSD

- CPU Intel Celeron J1900 - 4 GB RAM

- 17” LED ind. screen, Protection degree IP 65, 4:3 Format, Resolution: 1280x1024

- USB and Ethernet Ports

Ideal solution for small furniture manufacturers aiming to improve the quality of the manufacturing process on a small budget. To produce kitchens and bespoken pieces of furniture.

High-accuracy, versatility and productivity.

- User-friendly software interfacing

- Configurable equipment: choose Your solution!

- CNC programmable machining

- Small footprint: 3 sqm

- Easy maintenance, automatic lubrication of the axes and low power consumption

Ten-year experience, 100% made-in-Italy machines abiding by the highest quality standards as a result of the "Lean" manufacturing process, also known as "Toyota System".

- Italy

- New