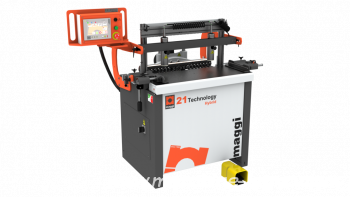

TECHNICAL FEATURES

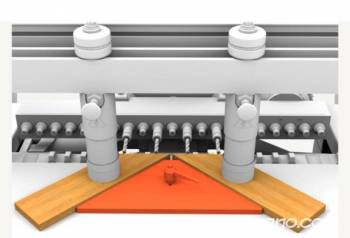

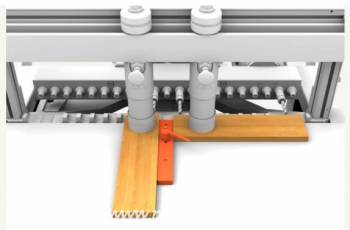

Quick-change spindles 32 mm interaxis. Electronic selecton of boring height, depth and boring angle from 0° to 90°. Well-dimensioned working table made of steel. Ready to be connected to a dust-collector. Manufactured according to EC standards.

STANDARD EQUIPMENT

n.1 aluminium boring-head with 21 spindles - 32 mm fixed interaxis

n.1 - 2HP Motor + linear actuator for boring-head tilting

n.2 stepper motors for the vertical and horizontal mouvement of the boring head

n.2 patented safety hold-down clamps

n.5 quick-change chucks

n.2, 1500 mm long, aluminium fences, with 4 ref. stops

n.2 removable side-fences on working table, adjustable on high-precision numeric counters

n.2 fixed ref. stops at 37 mm for hinges

Rear fence having 300 mm max. stroke

Ergonomic control panel, color 7" touch-screen, PLC for the electronic selection of the boring parameters

"Linux" Operative System

Up to 1.000 working programs storable

USB and Ethernet ports

Package:stackable carton box

Ready to be connected to a dust- collector

Manufactured according to EC standards

For horizontal and vertical drilling into wood-based panels and solid wood, for the furniture manufacturing.

- Quick, electronic set-up: Click and go!

- Accurate drilling: NC axes (+/- 0,1 mm) and the finest mechanical systems

- Small footprint: 1 sqm

More than 20.000 machines manufactured, over thirty years' experience.

100% made-in-Italy machines abiding by the highest quality standards as a result of the "Lean" manufacturing process, also known as "Toyota System"

- Italy

- New