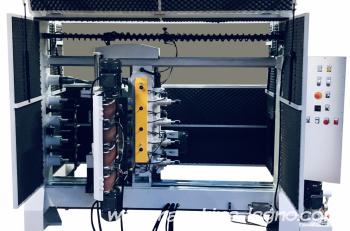

Windoor plus - double operating unit with 9 axes for panel - door processing

Automatic machine which assures a great reliability, an extreme accurancy and an high productivity in the workings on the both the sides of the panel at the same time: thanks to its advanced technologies, to the sturdiness and stiffness of its structure and to the employed materials.

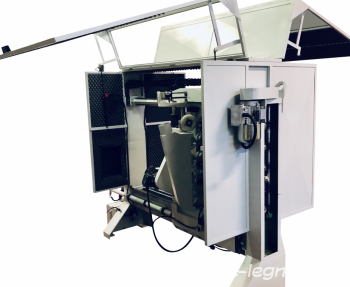

OLEOPNEUMATICALLY CONTROLLED AUTOMATIC VERTICAL COPYING LATHE

STANDARD EQUIPMENT

4 pcs. spindles for simultaneous copying of 4 workpieces.

Variable rotation by inverter.

Spindle movement by bronze gears and worm screw.

Centerers for automatic positioning of workpieces.

Pneumatic presses.

Approch and moving away of cutter unit by pneumatic system.

Indipendent adjustement of cutter carriage advance and woods rotation.

Oleodynamic advance of cutter - holder carriage.

Machine and electric installation in compliance with EC rules.

TECHNICAL DATA

Max.turning length mm 1200.

Max.turning diameter mm 150.

Cutter motor power V 380 / 50 - Kw 5,5.

Spindles rotation motor power V 380 / 50 - Kw 0,75.

Oleodynamic installation motor power V 380 / 50 - Kw 0,75.

Tools-holder diameter mm 145.

Tool diameter mm 35.

Variable carriage advance speed mm/min 0 ÷ 600.

Variable spindle rotation speed RPM 20 ÷ 50.

Tools speed RPM 4500.

OPTIONAL

Max turning length mm 1500.

Grinder mod. NV with one vertical belt, motor V 380 / 50 - Kw 0,75.

Grinder mod. 4NO with 4 horizontal belt, motor V 380 / 50 - Kw 0,75.

Voltages different from the standard.

- Italy

- New