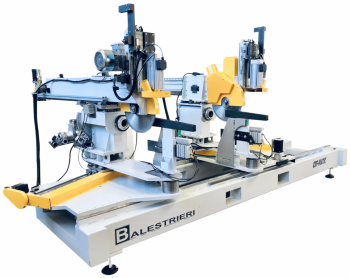

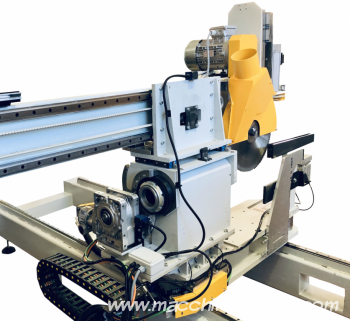

Cof-matic - double automatic mitre sawing and milling machine (double inclinations blade groups tilting and rotating system for saw and milling units)

Specially studied for coffins processing operations.

STANDARD EQUIPMENT

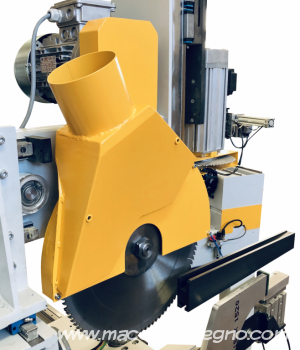

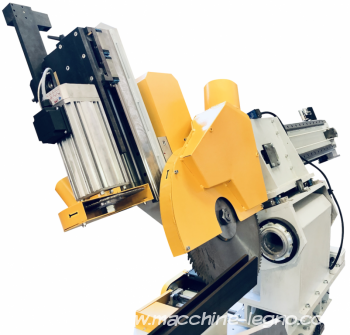

NR.2 cutting Units: Max. blade/cutter inclination 48°; Max. unit rotation 45°; Units feed by CC motors set on keyboard; Detachment of the blades on the units way back.

NR.2 milling Units jointly connected with the Cutting Units, they start to work at the end ofcutting operations.

NR.5 moving axes controlled by CN and set on touch-screen keyboard touch-screen. (angle and length adjustment with Brushless electronically controlled motors that can be set from the keyboard)

NR.2 resting tables with vertical pressing devices (zero point reference on the top side).

Cycle start command on console.

Dust suction inlet.

Power supply 400 V / 50 Hz - 3-phase + N.

TECHNICAL DATA

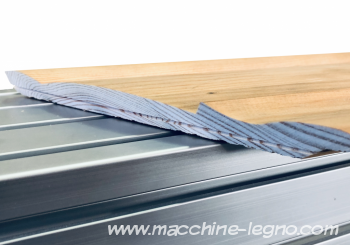

Max. cut thickness with blade inclination at 90°: 65 mm.

Max. cut thickness with blade inclination at 48°: 40 mm.

Min. cut length with blade group rotation at 90°: 300 mm.

Min. cut length with blade group rotation at 45°: 420 mm (alternating cut).

Max. cut width with blade group rotation at 90° and blade inclination at 90°: 400 mm with piece thickness of 65 mm; 500 mm with piece thickness of 40 mm;

Max. cut width with blade group rotation at 90° and blade inclination at 48°: 400 mm with piece thickness of 40 mm.

Max. cut width with blade group rotation at 45° and blade inclination at 90°: 280 mm with piece thickness of 65 mm; 350 mm with piece thickness of 40 mm;

Max. cut width with blade group rotation at 45° and blade inclination at 48°: 280 mm with piece thickness of 40 mm.

Usable cutting length mm 2500.

Blades diameter mm 450.

Blade motor power Kw 5,5.

Cutter motor power Kw 1,5.

EC version including the protection grille.

- Italy

- New