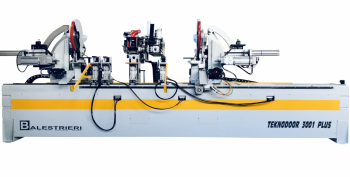

Teknodoor 3001 Plus - double mitre saw blades 90°/45° - automatic boring - milling lodging counterplates, zippers / concealed hinges, pivot hinges - pre-boring, screwing anuba

Automatic production unity for the workings of doors frames with coupling joint at 45°. Numerical control at 6 axes.

STANDARD EQUIPMENT

Mobile head cutting unit with motorized positioning. The sliding movement is made on tempered guides and ball recirculation racks.

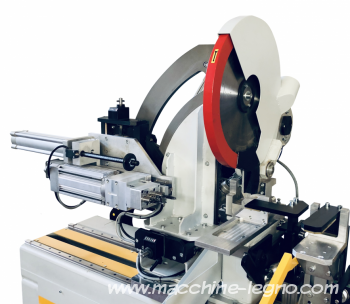

NR.2 Cutting units with blade of Ø 400: Each unit is driven by a motor of Kw 3.

NR.3 Support tables pieces supplied with pneumatic vertical clamps.

NR.1 Intermediate support table.

NR.2 Horizontal pneumatic clamps.

NR.1 Controlled axe for length programmer.

Automatic inclination of the blades.

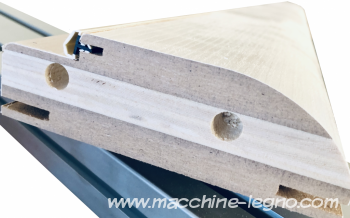

NR.2 Boring units assembled in a fixed position at 45°, supplied with head at 3 mandrels interface of 32 mm: Independent motors of Kw 1,5 (r.p.m. 5500); Sliding movement on rolling slide units; Mechanical reader for vertical and horizontal adjustments.

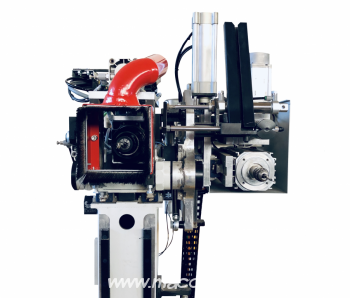

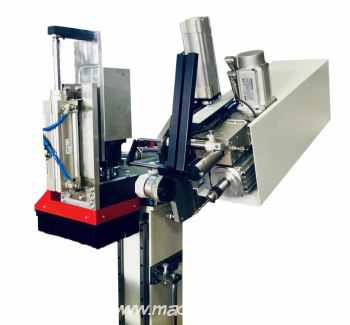

NR.1 Milling Unit with 3 controlled and interpolated axes.

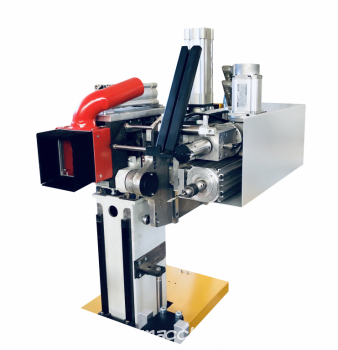

Hinges ANUBA boring and inserting with controlled inclination -5° +90°.

Electronic control with video: Software with easy graphic interface and default macros for standard works.

Nr.2 extension cords to work on door panel.

Pressor safety controlled by CNC.

TECHNICAL DATA

Motor for laying and drilling ANUBA Kw 1,5.

Motor for screwing ANUBA Nm 2,40 (with Brushless motor where, by program control, it is possible to the depth).

Max. with of the door frames 210 mm.

Max height of the cut: 80 mm (with blades at 45°); 120 mm (with blades at 90°).

Min. length of the cut: 880 mm (with blades at 45°); 680 mm (with blades at 45° with alternative cut); 650 mm (with blades at 90°).

Max. length of the cut 2800 mm - motor 1.3 Nm (C axis).

Milling unit (rotation 0° - 90°) with electro mandrel motor at Kw 3,3.

X axis work stroke 2500 mm – power 4,8 Nm.

Y axis work stroke 220 mm – power 2,4 Nm.

Z axis work stroke 100 mm – power 2,4 Nm.

Machine executed according to CE rules, included the perimetric protection.

OPTIONAL

Double loading for Anuba.

Kit for double-leg Anuba hinges. (suitable in the case that you utilize the anuba with double leg only)

Kit for double-leg Anuba hinges. (suitable in the case that you utilize both the anuba with 1 leg both the hinges anuba with double-leg)

Rotation of the boring units (0° - 45°).

Horizontal clamps for frames.

Additional milling/drilling unit with toll tongs ER 25 and 2 Kw Motor (for corners processing on seat hinges).

Additional milling unit with toll tongs ER 32 and 3,3 Kw Motor.

Table with nylon balls for the rotation of the panel door.

Electrical spindle at KW 5,6 - ER 32.

Electrical spindle with rapid change with pneumatic system of the tools.

Controlled inclination of the milling unit.

Automatic unloader.

- Italy

- New